Brand:

MITSUBISHI

R60TCRT4BW | MITSUBISHI Temperature control module R60TCRT4BW

MITSUBISHI R60TCRT4BW Manual And Instructions

R60TCRT4BW datasheetPDF datasheet

MITSUBISHI R60TCRT4BW Product information and technical parameters:

Brand: MITSUBISHI

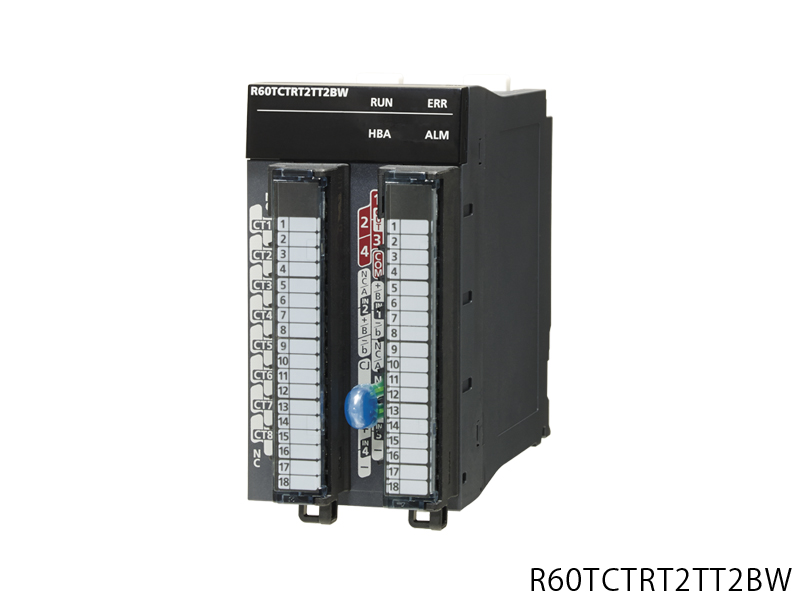

Name: Temperature control module

Model: R60TCRT4BW

Analog input channel number: 4CH.

Available thermocouple: -.

Available temperature resistance: PT100, JPt100.

Sampling period 4CH: 250ms/500ms.

Control output cycle: 0.5s ~ 100.0s.

Input impedance: 1M.

Input filter (0: input filter OFF): 0 ~ 100s.

Sensor compensation value setting: the full range of the input range of the negative terminal to the full range of the input range.

Sensor input when the action: according to the scale of the processing.

Temperature control mode: ON/OFF PID pulse or 2 position control

Heater disconnection detection specification: there.

External wiring connection mode: 18 point screw terminal.

IQ-R MELSEC series of temperature control module to achieve a high stability and response to the temperature control.

Divided into Thermocouple Input, temperature resistance input two types of input,

These two kinds of input types are distinguished by the function of the detection of the broken line with / without heater.

Module binding function.

Combined with the use of up to 64 sets of temperature control module for temperature control. Can be combined with the function of the following two points.

Heating function between modules.

Peak current suppression function between modules.

By cooperating with the time of arrival of a number of loops, the average temperature is controlled.

Can realize the uniform temperature control, avoid partial burning control object,

Part of the phenomenon of thermal expansion. Can be divided into 16 groups, with its heating up to the time,

Reduce the overall system in heating up the waste of energy.

Peak current suppression function between modules

By the time staggered output transistor, suppressing peak current.

The power supply capacity of the equipment can be reduced by setting a larger channel and a smaller channel of the heater in the same set.

Can be divided into 5 groups.

...More relevant models >>>>

R60TCRT4BW datasheetPDF datasheet

MITSUBISHI R60TCRT4BW Product information and technical parameters:

Brand: MITSUBISHI

Name: Temperature control module

Model: R60TCRT4BW

Analog input channel number: 4CH.

Available thermocouple: -.

Available temperature resistance: PT100, JPt100.

Sampling period 4CH: 250ms/500ms.

Control output cycle: 0.5s ~ 100.0s.

Input impedance: 1M.

Input filter (0: input filter OFF): 0 ~ 100s.

Sensor compensation value setting: the full range of the input range of the negative terminal to the full range of the input range.

Sensor input when the action: according to the scale of the processing.

Temperature control mode: ON/OFF PID pulse or 2 position control

Heater disconnection detection specification: there.

External wiring connection mode: 18 point screw terminal.

IQ-R MELSEC series of temperature control module to achieve a high stability and response to the temperature control.

Divided into Thermocouple Input, temperature resistance input two types of input,

These two kinds of input types are distinguished by the function of the detection of the broken line with / without heater.

Module binding function.

Combined with the use of up to 64 sets of temperature control module for temperature control. Can be combined with the function of the following two points.

Heating function between modules.

Peak current suppression function between modules.

By cooperating with the time of arrival of a number of loops, the average temperature is controlled.

Can realize the uniform temperature control, avoid partial burning control object,

Part of the phenomenon of thermal expansion. Can be divided into 16 groups, with its heating up to the time,

Reduce the overall system in heating up the waste of energy.

Peak current suppression function between modules

By the time staggered output transistor, suppressing peak current.

The power supply capacity of the equipment can be reduced by setting a larger channel and a smaller channel of the heater in the same set.

Can be divided into 5 groups.

Operation control mode: stored procedure repeated operation.

Built in IE CC-Link.

Input / output points: 4096 points.

Program capacity: 160K step.

Easy to collect and display the value of soft component.

With simple parameter setting, the value of the soft component can be collected as the record data,

Save to the SD memory card, or through the USB/ Ethernet for real-time monitoring MITSUBISHI R60TCRT4BW R60TCRT4BW

Using the data collected by the recording function to support the Unicode text format,

Can be easily recognized by LogViewer GX and spreadsheet software.

In addition, LogViewer GX can also be used to monitor the function of real time,

Easily confirm the time of small changes in the object''s soft components.

These features can be traced back to improve and set up a fault when the commissioning of a great help MITSUBISHI R60TCRT4BW. Axis of control: 2.

Operation cycle: 0.444ms, 0.888ms, 1.777ms, 3.555ms.

Control unit: mm, inch, degree, pulse.

Location data: 600 data / axis.

Boot time (operation cycle 0.444ms, 1 axes): 0.7ms.

Servo amplifier connection mode: SSCNET III /H.

Inter station distance (max): 100m.

External wiring connection mode: 40 pin connector MITSUBISHI R60TCRT4BW.

Linear interpolation: 2 axes.

Arc interpolation: 2 axes.

Motion control by simple programming.

Can be realized through the software gear, shaft, transmission, cam action.

The most suitable for milling spiral line interpolation.

Normal start, high speed start, multi axis simultaneous start.

High precision ON/OFF pulse time measurement.

IQ-R MELSEC series of simple movement module, positioning module, high-speed counter module for intelligent function module,

High speed and high precision motion control, position control and position detection can be carried out by simple programming.

The simple motion module has the same operation convenience as the positioning module,

Like motion controller for synchronous control, cam control and other advanced control.

Can be connected to the servo system deedicated to support high-speed synchronous network /H III SSCNET servo amplifier R60TCRT4BW.

Positioning control (sealant / adhesive coating equipment etc.).

Synchronous control / electronic cam control (pick and place machine, packing machine, etc. R60TCRT4BW. ).

Speed / torque control (stamping machine, die casting machine, etc.).

Speed / position control switching (production of semiconductor chips, etc.).

Built in IE CC-Link.

Input / output points: 4096 points.

Program capacity: 160K step.

Easy to collect and display the value of soft component.

With simple parameter setting, the value of the soft component can be collected as the record data,

Save to the SD memory card, or through the USB/ Ethernet for real-time monitoring MITSUBISHI R60TCRT4BW R60TCRT4BW

Using the data collected by the recording function to support the Unicode text format,

Can be easily recognized by LogViewer GX and spreadsheet software.

In addition, LogViewer GX can also be used to monitor the function of real time,

Easily confirm the time of small changes in the object''s soft components.

These features can be traced back to improve and set up a fault when the commissioning of a great help MITSUBISHI R60TCRT4BW. Axis of control: 2.

Operation cycle: 0.444ms, 0.888ms, 1.777ms, 3.555ms.

Control unit: mm, inch, degree, pulse.

Location data: 600 data / axis.

Boot time (operation cycle 0.444ms, 1 axes): 0.7ms.

Servo amplifier connection mode: SSCNET III /H.

Inter station distance (max): 100m.

External wiring connection mode: 40 pin connector MITSUBISHI R60TCRT4BW.

Linear interpolation: 2 axes.

Arc interpolation: 2 axes.

Motion control by simple programming.

Can be realized through the software gear, shaft, transmission, cam action.

The most suitable for milling spiral line interpolation.

Normal start, high speed start, multi axis simultaneous start.

High precision ON/OFF pulse time measurement.

IQ-R MELSEC series of simple movement module, positioning module, high-speed counter module for intelligent function module,

High speed and high precision motion control, position control and position detection can be carried out by simple programming.

The simple motion module has the same operation convenience as the positioning module,

Like motion controller for synchronous control, cam control and other advanced control.

Can be connected to the servo system deedicated to support high-speed synchronous network /H III SSCNET servo amplifier R60TCRT4BW.

Positioning control (sealant / adhesive coating equipment etc.).

Synchronous control / electronic cam control (pick and place machine, packing machine, etc. R60TCRT4BW. ).

Speed / torque control (stamping machine, die casting machine, etc.).

Speed / position control switching (production of semiconductor chips, etc.).

...More relevant models >>>>