Brand:

MITSUBISHI

FR-HEL-H15K | MITSUBISHI DC reactor FR-HEL-H15K

MITSUBISHI FR-HEL-H15K Manual And Instructions

FR-HEL-H15K datasheetPDF datasheet

MITSUBISHI FR-HEL-H15K Product information and technical parameters:

Brand: MITSUBISHI

Name: DC reactor

Model: FR-HEL-H15K

Power: 15kw.

Purpose: to suppress the power harmonics.

Improve the power factor, reduce the input side of the high harmonic current.

Make sure that this option is installed in the FR-A820-03800 (75K) and FR-A840-02160 (75K) and above capacity and above capacity.

At the same time the installation options in the use of 75kW and above motor. (the IP55 series has a built-in DC reactor.)

According to the motor power used to select the DC reactor.

(when the inverter capacity is greater than the motor capacity, is still based on the motor capacity to choose.)

...More relevant models >>>>

FR-HEL-H15K datasheetPDF datasheet

MITSUBISHI FR-HEL-H15K Product information and technical parameters:

Brand: MITSUBISHI

Name: DC reactor

Model: FR-HEL-H15K

Power: 15kw.

Purpose: to suppress the power harmonics.

Improve the power factor, reduce the input side of the high harmonic current.

Make sure that this option is installed in the FR-A820-03800 (75K) and FR-A840-02160 (75K) and above capacity and above capacity.

At the same time the installation options in the use of 75kW and above motor. (the IP55 series has a built-in DC reactor.)

According to the motor power used to select the DC reactor.

(when the inverter capacity is greater than the motor capacity, is still based on the motor capacity to choose.)

MITSUBISHI inverter series: FR-A820.

Voltage level: three phase 200V.

Power: 45kw.

SLD converter rated current: 233A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight) MITSUBISHI FR-HEL-H15K.

Type load) for selection FR-HEL-H15K

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

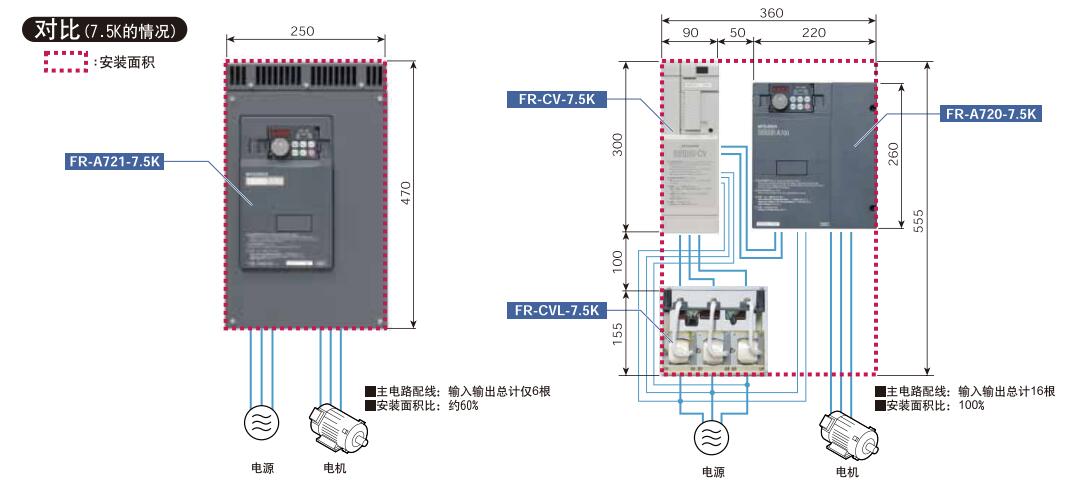

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable MITSUBISHI FR-HEL-H15K.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Superior high efficiency IPM motor.

Output power: 30kw.

Rated speed: 1500r/min.

Voltage level: 200V.

IPM motor MM-EFS series can not be used to run the power frequency power MITSUBISHI FR-HEL-H15K.

The total wiring length of the IPM motor shall not exceed 100m.

1 inverters can not connect multiple IPM motors at the same time. MITSUBISHI inverter FR-E720 series.

Voltage level: 3 phase 200V.

Frequency converter capacity: 1.5KW.

In order to ensure the reliability of production, all production machinery in the design of power with drive, there is a certain amount of surplus.

When the motor can not run under full load, in addition to meet the requirements of power driven,

The surplus torque increases the active power consumption, resulting in the waste of electric energy.

Speed control method of fan andd pump equipment traditional by regulating the entrance or exit of the baffle, valve opening to regulate air flow and water flow

, the input power is large, and a large amount of energy consumption in the baffle, the valve in the processs of closure FR-HEL-H15K FR-HEL-H15K.

When using variable frequency control, if the flow rate is reduced, the speed of the pump or fan can be reduced to meet the requirements.

Voltage level: three phase 200V.

Power: 45kw.

SLD converter rated current: 233A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight) MITSUBISHI FR-HEL-H15K.

Type load) for selection FR-HEL-H15K

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable MITSUBISHI FR-HEL-H15K.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Superior high efficiency IPM motor.

Output power: 30kw.

Rated speed: 1500r/min.

Voltage level: 200V.

IPM motor MM-EFS series can not be used to run the power frequency power MITSUBISHI FR-HEL-H15K.

The total wiring length of the IPM motor shall not exceed 100m.

1 inverters can not connect multiple IPM motors at the same time. MITSUBISHI inverter FR-E720 series.

Voltage level: 3 phase 200V.

Frequency converter capacity: 1.5KW.

In order to ensure the reliability of production, all production machinery in the design of power with drive, there is a certain amount of surplus.

When the motor can not run under full load, in addition to meet the requirements of power driven,

The surplus torque increases the active power consumption, resulting in the waste of electric energy.

Speed control method of fan andd pump equipment traditional by regulating the entrance or exit of the baffle, valve opening to regulate air flow and water flow

, the input power is large, and a large amount of energy consumption in the baffle, the valve in the processs of closure FR-HEL-H15K FR-HEL-H15K.

When using variable frequency control, if the flow rate is reduced, the speed of the pump or fan can be reduced to meet the requirements.

...More relevant models >>>>