Brand:

MITSUBISHI

FR-BU2-3.7K | MITSUBISHI Brake unit FR-BU2-3.7K

MITSUBISHI FR-BU2-3.7K Manual And Instructions

FR-BU2-3.7K datasheetPDF datasheet

MITSUBISHI FR-BU2-3.7K Product information and technical parameters:

Brand: MITSUBISHI

Name: Brake unit

Model: FR-BU2-3.7K

Power: 3.7kw.

Voltage: 200V.

Purpose: high frequency braking resistor.

The braking ability provided by the braking capacity is larger than that provided by the external braking resistor.

Can also be connected without built-in brake transistor inverter.

Three types of discharge resistors are available.

Please select according to the required braking torque.

...More relevant models >>>>

FR-BU2-3.7K datasheetPDF datasheet

MITSUBISHI FR-BU2-3.7K Product information and technical parameters:

Brand: MITSUBISHI

Name: Brake unit

Model: FR-BU2-3.7K

Power: 3.7kw.

Voltage: 200V.

Purpose: high frequency braking resistor.

The braking ability provided by the braking capacity is larger than that provided by the external braking resistor.

Can also be connected without built-in brake transistor inverter.

Three types of discharge resistors are available.

Please select according to the required braking torque.

MITSUBISHI inverter series: FR-A820.

Voltage level: three phase 200V.

Power: 37kw.

SLD converter rated current: 187A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight) MITSUBISHI FR-BU2-3.7K.

Type load) for selection FR-BU2-3.7K

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

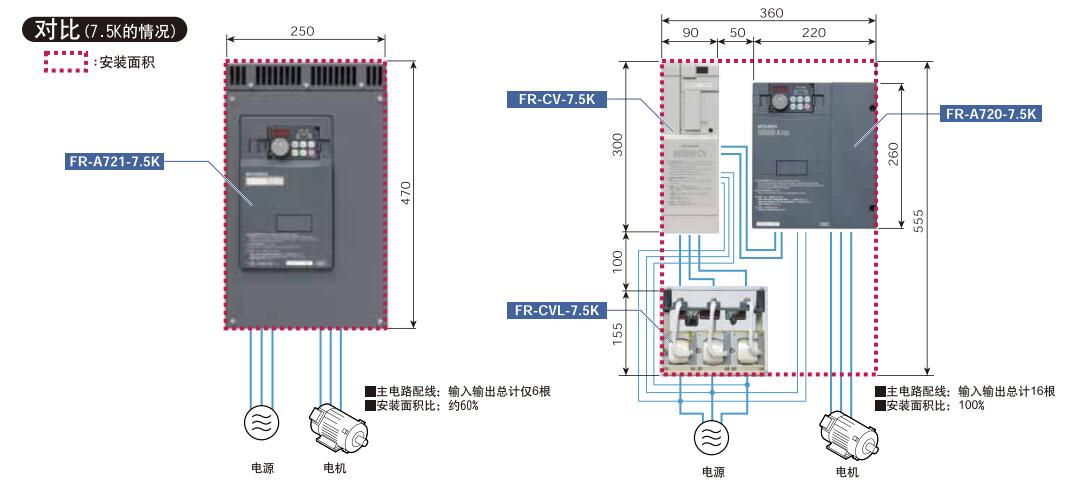

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable MITSUBISHI FR-BU2-3.7K.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Purpose: to operate, monitor, and change the parameters through the network.

Applicable frequency converter: FR-A700, FR-F700, FR-E700. MITSUBISHI inverter series: FR-F840 MITSUBISHI FR-BU2-3.7K.

Voltage level: three phase 400V.

Power: 75kw.

SLD converter rated current: 180A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

The motor efficiency is not changed in the previous optimal excitation control,

At the same time, the newly developed advanced optimal excitation control can obtain larger torque at startup.

No need to adjust the parameters (plus deceleration time or torque, etc.), in a short time to speed up to a certain speed,

Can be carried out to maximize the efficiency of energy-saving drive motor.

The automatic tuning function of the loop constant of the motor is not consistent with the constant of the motor, the motor of other manufacturers, and the length of wiring is too long,

Optimum operating characteriistic drive motor FR-BU2-3.7K.

In the state of the sensor can not only drive the high efficiency and energy saving motor and PM motor (MM-EFS), but also can drive other companies induction motor and PM motor (permanent magnet synchronous motor).

Othher manufacturers of induction motors, can also be automatically tuned to achieve the best excitation control, thus expanding the use of energy saving FR-BU2-3.7K.

Voltage level: three phase 200V.

Power: 37kw.

SLD converter rated current: 187A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

Parameters can be selected by 4 different rated current and different overload rating (SLD (ultra light load) rated, LD (light load) rating, ND (general load) rating, HD (weight) MITSUBISHI FR-BU2-3.7K.

Type load) for selection FR-BU2-3.7K

You can choose the most suitable frequency converter for use; and by selecting a transducer with a SLD or LD rated level,

Be able to reduce the size of the device (compared with the FR-A700 series, to reduce the volume of equipment).

For applications that require high torque at low speeds, the HD rating is the most suitable MITSUBISHI FR-BU2-3.7K.

The controller is used to control and monitor the frequency converter through the network.

Standard corresponding RS-485 communication (MITSUBISHI converter protocol, Modbus-RTU protocol) data transmission speed up to 115200bps. Purpose: to operate, monitor, and change the parameters through the network.

Applicable frequency converter: FR-A700, FR-F700, FR-E700. MITSUBISHI inverter series: FR-F840 MITSUBISHI FR-BU2-3.7K.

Voltage level: three phase 400V.

Power: 75kw.

SLD converter rated current: 180A.

Structure and function: Standard model.

Type: CA.

Substrate coating: have.

The motor efficiency is not changed in the previous optimal excitation control,

At the same time, the newly developed advanced optimal excitation control can obtain larger torque at startup.

No need to adjust the parameters (plus deceleration time or torque, etc.), in a short time to speed up to a certain speed,

Can be carried out to maximize the efficiency of energy-saving drive motor.

The automatic tuning function of the loop constant of the motor is not consistent with the constant of the motor, the motor of other manufacturers, and the length of wiring is too long,

Optimum operating characteriistic drive motor FR-BU2-3.7K.

In the state of the sensor can not only drive the high efficiency and energy saving motor and PM motor (MM-EFS), but also can drive other companies induction motor and PM motor (permanent magnet synchronous motor).

Othher manufacturers of induction motors, can also be automatically tuned to achieve the best excitation control, thus expanding the use of energy saving FR-BU2-3.7K.

...More relevant models >>>>