Brand:

MITSUBISHI

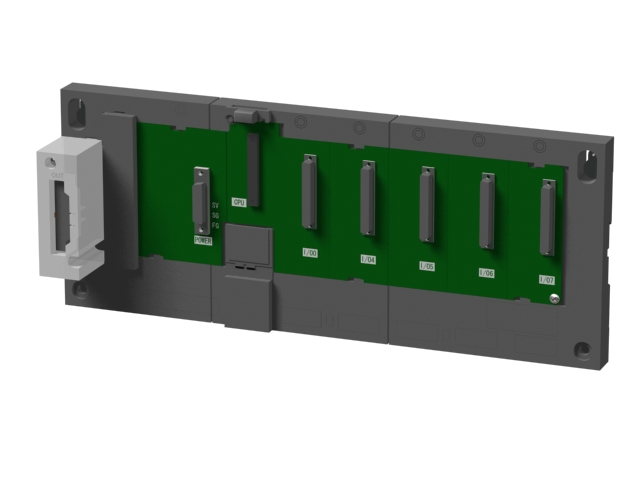

QA1S35B | MITSUBISHI Old small A series main substrate QA1S35B

MITSUBISHI QA1S35B Manual And Instructions

QA1S35B datasheetPDF datasheet

MITSUBISHI QA1S35B Product information and technical parameters:

Brand: MITSUBISHI

Name: Old small A series main substrate

Model: QA1S35B

5 slots; requires 1 AnS series PLC power modules;

Used to install large AnS series PLC module.

Base plate of AnS series PLC.

QA1S series PLC 5 slot main substrate.

AnS series of modules can be installed.

...More relevant models >>>>

QA1S35B datasheetPDF datasheet

MITSUBISHI QA1S35B Product information and technical parameters:

Brand: MITSUBISHI

Name: Old small A series main substrate

Model: QA1S35B

5 slots; requires 1 AnS series PLC power modules;

Used to install large AnS series PLC module.

Base plate of AnS series PLC.

QA1S series PLC 5 slot main substrate.

AnS series of modules can be installed.

Interface: RS232C.

Transmission distance: 15 meters.

A1SJ71UC24-R2/R4/PR computer communication components can communicate with PLC, such as computers and other external intelligent devices, and the components are as follows:

Full / half duplex transmission.

4 special communication protocols.

No protocol and bidirectional mode MITSUBISHI QA1S35B.

Protocol selection switch function.

The optional baud rate, the highest 19 QA1S35B2K.

Since the echo diagnostic test. SRAM memory card.

RAM capacity: 128KB. Output type: transistor source.

Output points: 32 points.

Load voltage: DC12/24.

Load current: 0.1A.

Connection: type D connector.

Common public end points: 32.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF MITSUBISHI QA1S35B.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control MITSUBISHI QA1S35B.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. Type of input: DC source.

Input points: 32 points.

Input voltage: DC24.

Input current: 7mA.

Connection mode: terminal row.

Common common point: 32.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functiional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the compllicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced QA1S35B QA1S35B.

Transmission distance: 15 meters.

A1SJ71UC24-R2/R4/PR computer communication components can communicate with PLC, such as computers and other external intelligent devices, and the components are as follows:

Full / half duplex transmission.

4 special communication protocols.

No protocol and bidirectional mode MITSUBISHI QA1S35B.

Protocol selection switch function.

The optional baud rate, the highest 19 QA1S35B2K.

Since the echo diagnostic test. SRAM memory card.

RAM capacity: 128KB. Output type: transistor source.

Output points: 32 points.

Load voltage: DC12/24.

Load current: 0.1A.

Connection: type D connector.

Common public end points: 32.

Switching value, also known as logic, refers to only two values, 0 or 1, ON or OFF MITSUBISHI QA1S35B.

It is the most common control, it is the advantage of PLC control,

Is also the most basic application of PLC.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order.

So, sometimes also known as the order control MITSUBISHI QA1S35B.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. Type of input: DC source.

Input points: 32 points.

Input voltage: DC24.

Input current: 7mA.

Connection mode: terminal row.

Common common point: 32.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functiional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the compllicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced QA1S35B QA1S35B.

...More relevant models >>>>