Brand:

MITSUBISHI

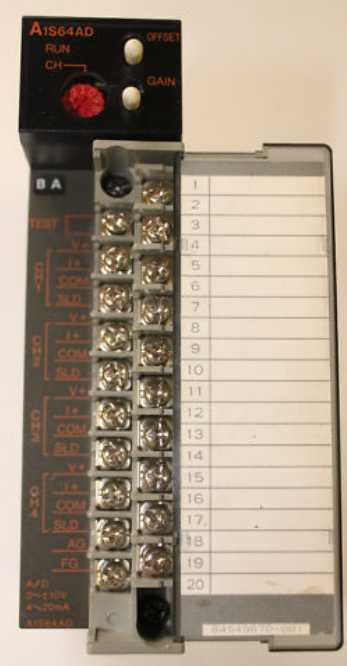

A1S64AD | MITSUBISHI Analog input module A1S64AD

MITSUBISHI A1S64AD Manual And Instructions

A1S64AD datasheetPDF datasheet

A1S64AD HardwareUser's Manual

A1S64AD User's Manual

MITSUBISHI A1S64AD Product information and technical parameters:

Brand: MITSUBISHI

Name: Analog input module

Model: A1S64AD

4 channel analog input module.

A1S64AD analog input module can accept the voltage or current signal,

The built-in microprocessor converts these signals to binary values,

For the control program to enjoy.

Signal can be instantaneous read, can also be programmed time / frequency average,

The offset and gain value can be set, and this component also includes the following performance:

4 input channels.

High resolution digital output.

Total accuracy plus or minus 1%.

...More relevant models >>>>

A1S64AD datasheetPDF datasheet

A1S64AD HardwareUser's Manual

A1S64AD User's Manual

MITSUBISHI A1S64AD Product information and technical parameters:

Brand: MITSUBISHI

Name: Analog input module

Model: A1S64AD

4 channel analog input module.

A1S64AD analog input module can accept the voltage or current signal,

The built-in microprocessor converts these signals to binary values,

For the control program to enjoy.

Signal can be instantaneous read, can also be programmed time / frequency average,

The offset and gain value can be set, and this component also includes the following performance:

4 input channels.

High resolution digital output.

Total accuracy plus or minus 1%.

10BASE-T.3C-2V/5C-2V coaxial cable between double loop PC (control station / common station) / remote I/O network (remote master station).

Q mode.

When the programmer input programinto the user program memory,

Then CPU according to the function of the system (the system program memory to explain the compiler),

Translate the user program into PLC internally recognized by the user to compile the program MITSUBISHI A1S64AD A1S64AD

Input status and input information input from the input interface,

CPU will be stored in the working data memory or in the input image register.

And then combine the data and the program with CPU.

The result is stored in the output image register or the working data memory,

And then output to the output interface, control the external drive MITSUBISHI A1S64AD.

Semiconductor circuit with memory function.

System program memory and user memory.

System program memory for storing system program,

Including management procedures, monitoring procedures, as well as the user program to do the compiler to compile the process of interpretation.

Read only memory. Manufacturers use, content can not be changed, power does not disappear MITSUBISHI A1S64AD.

User memory: user program storage area and work data storage area.

Composed of random access memory (RAM). User use.

Power cut off. Commonly used efficient lithium battery as a backup power supply, life is generally 3~5 years. Output type: relay.

Output points: 16 points.

Load voltage: AC120/DC24.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 8.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functiional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the compllicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced A1S64AD A1S64AD.

Q mode.

When the programmer input programinto the user program memory,

Then CPU according to the function of the system (the system program memory to explain the compiler),

Translate the user program into PLC internally recognized by the user to compile the program MITSUBISHI A1S64AD A1S64AD

Input status and input information input from the input interface,

CPU will be stored in the working data memory or in the input image register.

And then combine the data and the program with CPU.

The result is stored in the output image register or the working data memory,

And then output to the output interface, control the external drive MITSUBISHI A1S64AD.

Semiconductor circuit with memory function.

System program memory and user memory.

System program memory for storing system program,

Including management procedures, monitoring procedures, as well as the user program to do the compiler to compile the process of interpretation.

Read only memory. Manufacturers use, content can not be changed, power does not disappear MITSUBISHI A1S64AD.

User memory: user program storage area and work data storage area.

Composed of random access memory (RAM). User use.

Power cut off. Commonly used efficient lithium battery as a backup power supply, life is generally 3~5 years. Output type: relay.

Output points: 16 points.

Load voltage: AC120/DC24.

Load current: 2A.

Connection mode: terminal row.

Common public end points: 8.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functiional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the compllicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced A1S64AD A1S64AD.

...More relevant models >>>>