Brand:

MITSUBISHI

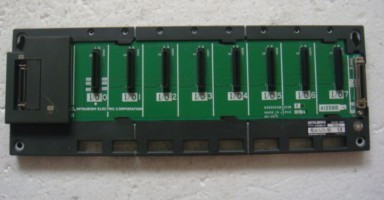

A1S58B-S1 | MITSUBISHI Extended substrate A1S58B-S1

MITSUBISHI A1S58B-S1 Manual And Instructions

A1S58B-S1 datasheetPDF datasheet

MITSUBISHI A1S58B-S1 Product information and technical parameters:

Brand: MITSUBISHI

Name: Extended substrate

Model: A1S58B-S1

I/O slots: 8 slots.

Can you install the power module.

Outline dimension: 365*130.

There are two types of extended floor,

A power module can be inserted, and the other one is not.

The choice of any type of substrate depends on the total DC5V current consumption and the power supply on the CPU main substrate.

If the total demand is less than the power output, no additional power supply,

Then you can choose a more economical expansion board.

Both ends of the main base plate of the CPU have an expansion interface, and can be used for extending the cable connection.

...More relevant models >>>>

A1S58B-S1 datasheetPDF datasheet

MITSUBISHI A1S58B-S1 Product information and technical parameters:

Brand: MITSUBISHI

Name: Extended substrate

Model: A1S58B-S1

I/O slots: 8 slots.

Can you install the power module.

Outline dimension: 365*130.

There are two types of extended floor,

A power module can be inserted, and the other one is not.

The choice of any type of substrate depends on the total DC5V current consumption and the power supply on the CPU main substrate.

If the total demand is less than the power output, no additional power supply,

Then you can choose a more economical expansion board.

Both ends of the main base plate of the CPU have an expansion interface, and can be used for extending the cable connection.

Using A6SIM-X64Y64 simulation I/O module in the system before the connection can be carried out to control the process of debugging.

The simulation unit consists of 16 blocks of 4 switches and 4 LED LEDs. Output type: relay.

Output points: 16 points.

Load voltage: AC120/DC24.

Load current: 2A.

Connection mode: terminal row MITSUBISHI A1S58B-S1.

Common public end points: 8.

Sequential function flow chart language is designed to satisfy the sequential logic control A1S58B-S1

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box MITSUBISHI A1S58B-S1.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions MITSUBISHI A1S58B-S1.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced. Three remote components can be connected to the CC-LINK system.

Remote I/O: refers to the field components that require only ON/OFF control,

Such as digital I/O or pneumatic valve, etc..

In this type of communication can only be carried out in the bit data.

Remote components: the field components that require processing of register data,

For example analog I/O and counter, etc..

In this type of component, in addition to the bit data can be carried out in the register data communication.

Intelligent remote: this type of element refers to the actions that allow the master station or other station to access,

To collect data and control the local PLC station,

GOTS and programmer interface unit are of this type.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence number (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next round of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence numberr (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next rround of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work A1S58B-S1 A1S58B-S1.

The simulation unit consists of 16 blocks of 4 switches and 4 LED LEDs. Output type: relay.

Output points: 16 points.

Load voltage: AC120/DC24.

Load current: 2A.

Connection mode: terminal row MITSUBISHI A1S58B-S1.

Common public end points: 8.

Sequential function flow chart language is designed to satisfy the sequential logic control A1S58B-S1

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box MITSUBISHI A1S58B-S1.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions MITSUBISHI A1S58B-S1.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced. Three remote components can be connected to the CC-LINK system.

Remote I/O: refers to the field components that require only ON/OFF control,

Such as digital I/O or pneumatic valve, etc..

In this type of communication can only be carried out in the bit data.

Remote components: the field components that require processing of register data,

For example analog I/O and counter, etc..

In this type of component, in addition to the bit data can be carried out in the register data communication.

Intelligent remote: this type of element refers to the actions that allow the master station or other station to access,

To collect data and control the local PLC station,

GOTS and programmer interface unit are of this type.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence number (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next round of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work.

PLC is the use of " sequential scanning, and constantly circulating " way to work.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence numberr (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next rround of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work A1S58B-S1 A1S58B-S1.

...More relevant models >>>>