Brand Sort:

MITSUBISHI

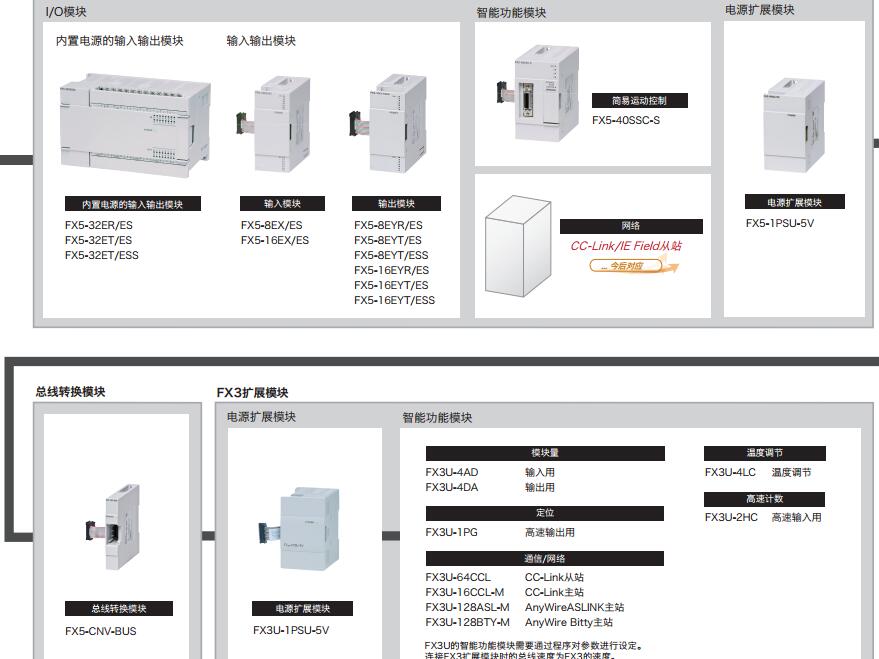

FX5-16EYT/ESS Market price | FX5-16EYT/ESS Introduction

- Brand: MITSUBISHI

- Country: JAPAN

- Name: output module

- Model: FX5-16EYT/ESS

- Price: 0 >

MITSUBISHI FX5-16EYT/ESS

MODBUS/TCP Master slave station.

10BASE-T/100BASE-TX.

MODBUS interface module capable of connecting MODBUS compatible device such as temperature regulator, measuring device and so on.

Support MODBUS communication function, and can be compatible with the third party MODBUS to communicate from various station equipment.

Support MODBUS communication functions from the station, can communicate with the third party programmable controller MODBUS master device FX5-16EYT/ESS

Through the linkage function, the master can be connected to the CH1 side (RS-232),

And through the QJ71MB91 and connected to the CH2 side (RS-422/485) of a number of stations for communication.

The RS-232 interface (1 credit on the 1 pass) MODBUS master device with multiple MODBUS communication from the station equipment. (only QJ71MB91)

Master / slave station functions can be used simultaneously. (only QJ71MT91)Power: 220kw.

Voltage: 200V.

Sine wave filter.

The voltage and current of the motor can be adjusted to a sine wave.

The sine wave filter is installed to the output terminal of the inverter.

Applicable to FR-A820-03800 (75K) above and FR-A840-02160 (75K) and above frequency converter.

Sine wave filter is equivalent to the operational characteristics of the sine wave power driver, can provide the following benefits.

Low noise.

No surge current.

Reduce motor loss (standard motor). DC input points: 16 points.

Input voltage and current: 3/7mA, DC12/24V.

Response time: 10ms.

Positive pole sharing.

16 point /1 a public side.

Output points: 12 points.

Output voltage and current: DC12/24V, 0.5A/1 point, 3.2A/1 common end.

Response time: 2ms.

8 point /1 a public end, 4 point /1 a public end.

Output form: transistor output, leakage type.

36 point terminal station.

Number of stations: 4 stops.

Compact remote I/O unit.

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system.

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

FX5-16EYT/ESS Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FX5-16EYT/ESS&select=5

10BASE-T/100BASE-TX.

MODBUS interface module capable of connecting MODBUS compatible device such as temperature regulator, measuring device and so on.

Support MODBUS communication function, and can be compatible with the third party MODBUS to communicate from various station equipment.

Support MODBUS communication functions from the station, can communicate with the third party programmable controller MODBUS master device FX5-16EYT/ESS

Through the linkage function, the master can be connected to the CH1 side (RS-232),

And through the QJ71MB91 and connected to the CH2 side (RS-422/485) of a number of stations for communication.

The RS-232 interface (1 credit on the 1 pass) MODBUS master device with multiple MODBUS communication from the station equipment. (only QJ71MB91)

Master / slave station functions can be used simultaneously. (only QJ71MT91)Power: 220kw.

Voltage: 200V.

Sine wave filter.

The voltage and current of the motor can be adjusted to a sine wave.

The sine wave filter is installed to the output terminal of the inverter.

Applicable to FR-A820-03800 (75K) above and FR-A840-02160 (75K) and above frequency converter.

Sine wave filter is equivalent to the operational characteristics of the sine wave power driver, can provide the following benefits.

Low noise.

No surge current.

Reduce motor loss (standard motor). DC input points: 16 points.

Input voltage and current: 3/7mA, DC12/24V.

Response time: 10ms.

Positive pole sharing.

16 point /1 a public side.

Output points: 12 points.

Output voltage and current: DC12/24V, 0.5A/1 point, 3.2A/1 common end.

Response time: 2ms.

8 point /1 a public end, 4 point /1 a public end.

Output form: transistor output, leakage type.

36 point terminal station.

Number of stations: 4 stops.

Compact remote I/O unit.

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system.

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

FX5-16EYT/ESS Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FX5-16EYT/ESS&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

output module

FX5-16EYT/ESS

Input / output type: transistor output

MITSUBISHI

output module

FX5-16EYR/ES

Input / output form: relay output.

Outpu

MITSUBISHI

output module

FX5-16EYT/ES

Input / output mode: transistor output

MITSUBISHI

Input module

FX5-16EX/ES

Input / output type: DC input drain / s