Brand Sort:

MITSUBISHI

FR-A540-3.7K-CH Market price | FR-A540-3.7K-CH Introduction

- Brand: MITSUBISHI

- Country: JAPAN

- Name:

- Model: FR-A540-3.7K-CH

- Price: U.S.$ 1444.07

MITSUBISHI FR-A540-3.7K-CH

Control axis: maximum 8 axes.

Greater flexibility.

PLC control and motion control using independent CPU, optimize the system configuration.

More than 4 CPU modules can be freely selected in multi CPU system.

MITSUBISHI SSCNET control function.

By using the high speed serial communication mode, we can easily construct the synchronization system of the servo motor.

The motion controller and the servo amplifier can be quickly connected by a connector, and the connection is simplified FR-A540-3.7K-CH

Each 1 CPU can control up to 32 axes at the same time.

Can control the small capacity from 10W to 55KW large capacity servo motor.

Through the use of digital oscilloscope function, can be used to control the power distance, speed, position and other motor information monitoring.MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 0.75kw.

Interface type: SSCNET type III fiber communication.

Special specification: suitable for direct drive servo motor.

Power specification: single phase AC200V.

Direct drive system suitable for high speed and high precision!

High speed operation can be realized by direct drive (2m/s), and the traditional mechanical transmission can not achieve such a high speed.

The full closed loop control can be realized by using the position feedback signal from the load side encoder, such as the linear encoder.

The use of a flexible linear servo motor drive components can make the system more compact structure.

The primary side of the linear servo motor (motor coil) is sliding along the secondary side (permanent magnet) of the motor,

So linear servo motor is especially suitable for large range of applications. In addition, linear servo motor can be connected in series,

Especially for large systems in two axes for high precision synchronous operation. Input: 4 channels.

Thermocouple (K, J, T, B, S, E, R, N, U, L, PLlI, W5Re/W26Re,,).

No heater disconnection detection function.

Sampling period: 0.5s/4 channel.

18 point terminal station.

Peak current suppression.

Can prevent the simultaneous opening of the output to control the peak current, which is helpful for saving energy and reducing the operation cost.

Heating function at the same time.

The multiple loop can reach the set value at the same time to carry out the uniform temperature control,

Helps to prevent no-load and effective energy saving and reduce operating costs.

Automatic adjustment function.

The PID constant can be adjusted automatically in the control process.

Automatic adjustment of cost (time, material and electrical energy) can be reduced.

Can be flexible in various settings, to achieve the best temperature control of the temperature control module.

Equipment for high temperature control stability of extrusion molding machine,

The temperature regulating module has the function of preventing overheating and preventing over cooling.

According to the control object device, select the standard control (heating or cooling) or the heating and cooling control (heating and cooling) mode.

In addition, the mixed control mode (combined with the standard control and heating - cooling control) can be selected.

FR-A540-3.7K-CH Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FR-A540-3.7K-CH&select=5

Greater flexibility.

PLC control and motion control using independent CPU, optimize the system configuration.

More than 4 CPU modules can be freely selected in multi CPU system.

MITSUBISHI SSCNET control function.

By using the high speed serial communication mode, we can easily construct the synchronization system of the servo motor.

The motion controller and the servo amplifier can be quickly connected by a connector, and the connection is simplified FR-A540-3.7K-CH

Each 1 CPU can control up to 32 axes at the same time.

Can control the small capacity from 10W to 55KW large capacity servo motor.

Through the use of digital oscilloscope function, can be used to control the power distance, speed, position and other motor information monitoring.MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 0.75kw.

Interface type: SSCNET type III fiber communication.

Special specification: suitable for direct drive servo motor.

Power specification: single phase AC200V.

Direct drive system suitable for high speed and high precision!

High speed operation can be realized by direct drive (2m/s), and the traditional mechanical transmission can not achieve such a high speed.

The full closed loop control can be realized by using the position feedback signal from the load side encoder, such as the linear encoder.

The use of a flexible linear servo motor drive components can make the system more compact structure.

The primary side of the linear servo motor (motor coil) is sliding along the secondary side (permanent magnet) of the motor,

So linear servo motor is especially suitable for large range of applications. In addition, linear servo motor can be connected in series,

Especially for large systems in two axes for high precision synchronous operation. Input: 4 channels.

Thermocouple (K, J, T, B, S, E, R, N, U, L, PLlI, W5Re/W26Re,,).

No heater disconnection detection function.

Sampling period: 0.5s/4 channel.

18 point terminal station.

Peak current suppression.

Can prevent the simultaneous opening of the output to control the peak current, which is helpful for saving energy and reducing the operation cost.

Heating function at the same time.

The multiple loop can reach the set value at the same time to carry out the uniform temperature control,

Helps to prevent no-load and effective energy saving and reduce operating costs.

Automatic adjustment function.

The PID constant can be adjusted automatically in the control process.

Automatic adjustment of cost (time, material and electrical energy) can be reduced.

Can be flexible in various settings, to achieve the best temperature control of the temperature control module.

Equipment for high temperature control stability of extrusion molding machine,

The temperature regulating module has the function of preventing overheating and preventing over cooling.

According to the control object device, select the standard control (heating or cooling) or the heating and cooling control (heating and cooling) mode.

In addition, the mixed control mode (combined with the standard control and heating - cooling control) can be selected.

FR-A540-3.7K-CH Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FR-A540-3.7K-CH&select=5

...more relevant model market price >>>>

Related products

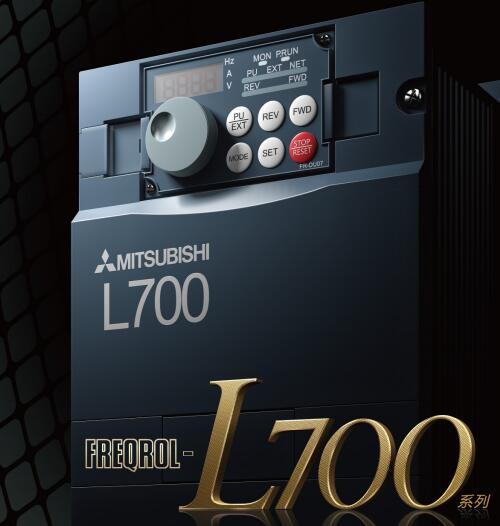

MITSUBISHI

3 phase 400V converter

FR-L740-3.7K-CHT

MITSUBISHI inverter FR-L740 series.

Volt

MITSUBISHI

3 phase 400V converter

FR-D740-3.7K-CHT

MITSUBISHI inverter FR-D740 series.

Volt

MITSUBISHI

Three phase 400V level inverter

IS74-3.7K-CHT

Applicale motor capacity: 3.7KW.

Rated

MITSUBISHI

3 phase 400V converter

FR-A740-3.7K-CHT

MITSUBISHI inverter FR-A740 series.

Volt