Brand Sort:

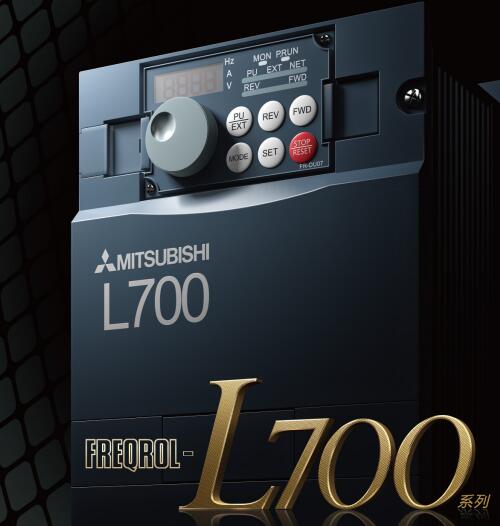

MITSUBISHI

FR-A520-15K Market price | FR-A520-15K Introduction

- Brand: MITSUBISHI

- Country: JAPAN

- Name:

- Model: FR-A520-15K

- Price: U.S.$ 3800

MITSUBISHI FR-A520-15K

Motor series: low inertia, medium capacity.

Rated output power: 15.0kw.

Rated speed: 1000rpm.

With the brake: without.

Shaft end: straight shaft.

The rotor of the servo motor is a permanent magnet, which is controlled by the U/V/W,

The rotor rotates under the action of the magnetic field, and the encoder feedback signal of the motor is given to the driver,

According to the feedback value and the target value, the driver adjusts the rotation angle of the rotor FR-A520-15K

Accuracy of the servo motor depends on the accuracy of the encoder (number of lines). Cable length: 30 meters.

PC to GOT long distance connection cable.

For connection between GOT and GOT. MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 37.0kw.

Interface type: SSCNET type III fiber communication.

Special features: integrated driver security.

Power specification: three phase AC200V.

STO function as a security feature is added to the SSCNET III fiber communication type servo amplifier.

By using the STO function, the electromagnetic contactor used in the past to prevent the motor from accidentally starting is no longer needed.

SS1 functions can be realized by using the MR-J3-D05 security logic unit.

MR-J3-BS uses a full closed loop control system.

Compatibility with MR-J3-B.

MR-J3-BS installation, wiring and connectors are the same as the MR-J3-B, so do not change the existing connection will be easy to MR-J3-B

Change to MR-J3-BS.

Security functions are connected to the CN8 interface through an external security circuit to increase the MR-J3-BS driver security.

Compatible full closed loop control system.

MR-J3-BS has a full closed loop control system version. Cable flat cable;

Connector with 20 pin installed at both ends of the fuse.

Length 3M. BASIC program running.

RS-232 2 channel, RS-422 1 channel.

Serial interface, memory card interface.

How to determine the input / output device of MITSUBISHI plc.

According to the control requirements of the system,

All input devices and output devices required for the determination of the system,

To determine the input / output device related to the MITSUBISHI PLC,

To determine the I/O PLC points.

Detailed analysis of the process and work characteristics of the controlled object,

To understand the coordination between the controlled object machine, electricity and liquid,

The control requirements of the controlled object for MITSUBISHI PLC control system are put forward,

Determine the control program, to develop a design task book.

FR-A520-15K Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FR-A520-15K&select=5

Rated output power: 15.0kw.

Rated speed: 1000rpm.

With the brake: without.

Shaft end: straight shaft.

The rotor of the servo motor is a permanent magnet, which is controlled by the U/V/W,

The rotor rotates under the action of the magnetic field, and the encoder feedback signal of the motor is given to the driver,

According to the feedback value and the target value, the driver adjusts the rotation angle of the rotor FR-A520-15K

Accuracy of the servo motor depends on the accuracy of the encoder (number of lines). Cable length: 30 meters.

PC to GOT long distance connection cable.

For connection between GOT and GOT. MITSUBISHI motor universal AC servo amplifier MELSERVO-J3 series.

Rated output: 37.0kw.

Interface type: SSCNET type III fiber communication.

Special features: integrated driver security.

Power specification: three phase AC200V.

STO function as a security feature is added to the SSCNET III fiber communication type servo amplifier.

By using the STO function, the electromagnetic contactor used in the past to prevent the motor from accidentally starting is no longer needed.

SS1 functions can be realized by using the MR-J3-D05 security logic unit.

MR-J3-BS uses a full closed loop control system.

Compatibility with MR-J3-B.

MR-J3-BS installation, wiring and connectors are the same as the MR-J3-B, so do not change the existing connection will be easy to MR-J3-B

Change to MR-J3-BS.

Security functions are connected to the CN8 interface through an external security circuit to increase the MR-J3-BS driver security.

Compatible full closed loop control system.

MR-J3-BS has a full closed loop control system version. Cable flat cable;

Connector with 20 pin installed at both ends of the fuse.

Length 3M. BASIC program running.

RS-232 2 channel, RS-422 1 channel.

Serial interface, memory card interface.

How to determine the input / output device of MITSUBISHI plc.

According to the control requirements of the system,

All input devices and output devices required for the determination of the system,

To determine the input / output device related to the MITSUBISHI PLC,

To determine the I/O PLC points.

Detailed analysis of the process and work characteristics of the controlled object,

To understand the coordination between the controlled object machine, electricity and liquid,

The control requirements of the controlled object for MITSUBISHI PLC control system are put forward,

Determine the control program, to develop a design task book.

FR-A520-15K Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=FR-A520-15K&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

3 phase 200V converter

FR-E720-15K

MITSUBISHI inverter FR-E720 series.

Volt

MITSUBISHI

3 phase 400V converter

FR-A740-15K-CHT

MITSUBISHI inverter FR-A740 series.

Volt

MITSUBISHI

Three phase 200V grade frequency converter

FR-A820-15K-1(FR-A820-00770-2-60)

MITSUBISHI inverter series: FR-A820.

Vol

MITSUBISHI

3 phase 400V converter

FR-L740-15K-CHT

MITSUBISHI inverter FR-L740 series.

Volt