Brand Sort:

MITSUBISHI

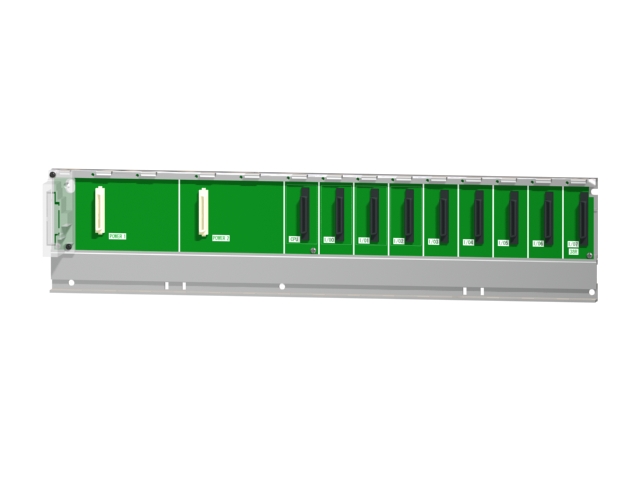

A32RB Market price | A32RB Introduction

- Brand: MITSUBISHI

- Country: JAPAN

- Name: floor

- Model: A32RB

- Price: U.S.$ 949.15

MITSUBISHI A32RB

Motor: HA-LH type.

Power: 22kw.

Speed: 2000r/min.

According to the types of power supply: can be divided into DC motor and AC motor.

The structure and working principle of DC motor can be divided into four parts: brushless DC motor and brushless DC motor.

Brushless DC motor can be divided into: permanent magnet DC motor and DC motor.

DC Motor Division: Series DC motor, DC motor, DC motor and DC motor A32RB

Permanent magnet DC Motor Division: rare earth permanent magnet DC motor, ferrite permanent magnet DC motor and aluminum nickel Gu Yongci DC motor. Safety grade (SIL): SIL 3 (IEC 61508).

Performance level (PL): e PL (13849-1 EN/ISO).

Operation control mode: stored procedures repeated operation.

Program capacity: 1200K (security program: 40K).

Program memory: 4800K.

Soft element / tag memory: 3370K.

Data memory: 40M.

Unified program development environment.

Whether the general control procedures or safety control procedures, can be integrated into 1 Engineering documents,

Unified management by Works3 GX. The troublesome operation can save more than one project file management.

When you create a security control program, you are also the same as when you create a general control program,

Various features of GXWorks3 can be developed using the support program.

Improve production efficiency through high responsiveness and rich program capacity.

Efficient use of high performance iQ-R CC-Link series and IE Field MELSEC networks,

Improve responsiveness and improve production efficiency.

In addition, the security control program capacity increased to 40K, about 3 times in the past.

Safe CPU can be used to deal with complex large capacity programs. Fast connector type.

Current input.

Number of channels: 8 channels.

Occupied the number of stations: Ver.1 mode occupied 3 stations, Ver.2 mode occupied 1 stations.

Station type: remote equipment station.

MITSUBISHI PLC hardware implementation

Hardware implementation is mainly for the control cabinet and other hardware design and field construction.

Design control cabinet and the operating table and other parts of the electrical wiring diagram and wiring diagram.

Electrical interconnection diagram of each part of the design system.

According to the construction drawings of the site wiring, and carry out a detailed inspection.

Because the program design and hardware implementation can be carried out at the same time,

So the design cycle of the MITSUBISHI PLC control system can be greatly reduced.

MITSUBISHI PLC online debugging.

On-line debugging is the process that will through the simulation debugging to further carry on the on-line unification to adjust.

On-line debugging process should be step by step,

From MITSUBISHI PLC only connected to the input device, and then connect the output device, and then connect to the actual load and so on and so on step by step.

If you do not meet the requirements, the hardware and procedures for adjustment.

Usually only need to modify the part of the program can be.

A32RB Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A32RB&select=5

Power: 22kw.

Speed: 2000r/min.

According to the types of power supply: can be divided into DC motor and AC motor.

The structure and working principle of DC motor can be divided into four parts: brushless DC motor and brushless DC motor.

Brushless DC motor can be divided into: permanent magnet DC motor and DC motor.

DC Motor Division: Series DC motor, DC motor, DC motor and DC motor A32RB

Permanent magnet DC Motor Division: rare earth permanent magnet DC motor, ferrite permanent magnet DC motor and aluminum nickel Gu Yongci DC motor. Safety grade (SIL): SIL 3 (IEC 61508).

Performance level (PL): e PL (13849-1 EN/ISO).

Operation control mode: stored procedures repeated operation.

Program capacity: 1200K (security program: 40K).

Program memory: 4800K.

Soft element / tag memory: 3370K.

Data memory: 40M.

Unified program development environment.

Whether the general control procedures or safety control procedures, can be integrated into 1 Engineering documents,

Unified management by Works3 GX. The troublesome operation can save more than one project file management.

When you create a security control program, you are also the same as when you create a general control program,

Various features of GXWorks3 can be developed using the support program.

Improve production efficiency through high responsiveness and rich program capacity.

Efficient use of high performance iQ-R CC-Link series and IE Field MELSEC networks,

Improve responsiveness and improve production efficiency.

In addition, the security control program capacity increased to 40K, about 3 times in the past.

Safe CPU can be used to deal with complex large capacity programs. Fast connector type.

Current input.

Number of channels: 8 channels.

Occupied the number of stations: Ver.1 mode occupied 3 stations, Ver.2 mode occupied 1 stations.

Station type: remote equipment station.

MITSUBISHI PLC hardware implementation

Hardware implementation is mainly for the control cabinet and other hardware design and field construction.

Design control cabinet and the operating table and other parts of the electrical wiring diagram and wiring diagram.

Electrical interconnection diagram of each part of the design system.

According to the construction drawings of the site wiring, and carry out a detailed inspection.

Because the program design and hardware implementation can be carried out at the same time,

So the design cycle of the MITSUBISHI PLC control system can be greatly reduced.

MITSUBISHI PLC online debugging.

On-line debugging is the process that will through the simulation debugging to further carry on the on-line unification to adjust.

On-line debugging process should be step by step,

From MITSUBISHI PLC only connected to the input device, and then connect the output device, and then connect to the actual load and so on and so on step by step.

If you do not meet the requirements, the hardware and procedures for adjustment.

Usually only need to modify the part of the program can be.

A32RB Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=A32RB&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

CPU unit

A3VCPU

Multiple CPU units for A3VTS multiplex s

MITSUBISHI

Main substrate of redundant system of power supply

Q38RB

8 slots.

The main sustrate needs to e

MITSUBISHI

CPU unit

A3NCPUR21

Input and output points: 2048 points.

In

MITSUBISHI

floor

A37RHB

7 slots.

Power supply unit.

Q4AR power s