Brand Sort:

MITSUBISHI

HC-RF353B Market price | HC-RF353B Introduction

- Brand: MITSUBISHI

- Country: JAPAN

- Name: Low inertia medium capacity motor

- Model: HC-RF353B

- Price: 0 >

MITSUBISHI HC-RF353B

Type: HA-FH series.

Rated output: 0.4KW.

Rated speed: 3000r/min.

Electromagnetic brake: there.

From the vector control technology of AC servo motor, it has become more and more popular.

From the point of view of the real time operating system, it is just a function module that needs to be processed in real time.

Due to the multi function of the controller, intelligent requirements, a large number of signal processing,

Establishment and operation of various mathematical models of adaptive control,

Network communications and other functional modules will be in the real-time operation of the unified scheduling and management of the system to get the correct and reliable operation HC-RF353B

Therefore, the next generation of servo drive controller will be a collection of various modern control technology of the crystallization,

Instead of the traditional sense of power amplifier. Input type: DC input, positive common end.

Input points: 8 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/5mA.

Output form: transistor output, leakage type.

Output points: 8 points.

OFF leakage current: 0.1mA.

Output protection function: No.

Rated load voltage / current: DC24V/0.5A.

External connection: 4 wire.

Fast connector type.

Simple wiring through quick connector.

Can be installed along the 6 direction.

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation. Drive: MR-H_AN series.

Rated output: 15KW.

Universal AC servo.

Servo driver (drives servo) also known as the "servo controller", "servo amplifier",

Is a kind of controller used to control the servo motor. Its function is similar to that of the frequency converter,

Belongs to a part of the servo system, which is mainly used in high precision positioning system.

In general, the servo motor is controlled by position, speed and torque in three ways,

To achieve high precision positioning of the transmission system, the current transmission technology is the high-end products.

Servo drive is an important part of modern motion control,

Is widely used in industrial robots and CNC machining centers and other automation equipment.

In particular, it has become a hot research topic in the field of servo drives for the control of AC permanent magnet synchronous motor.

Current, speed and position 3 closed loop control algorithm based on vector control is widely used in AC servo drive system.

The speed closed-loop design of the algorithm is reasonable or not, for the entire servo control system,

Especially the speed control performance plays a key role.

HC-RF353B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-RF353B&select=5

Rated output: 0.4KW.

Rated speed: 3000r/min.

Electromagnetic brake: there.

From the vector control technology of AC servo motor, it has become more and more popular.

From the point of view of the real time operating system, it is just a function module that needs to be processed in real time.

Due to the multi function of the controller, intelligent requirements, a large number of signal processing,

Establishment and operation of various mathematical models of adaptive control,

Network communications and other functional modules will be in the real-time operation of the unified scheduling and management of the system to get the correct and reliable operation HC-RF353B

Therefore, the next generation of servo drive controller will be a collection of various modern control technology of the crystallization,

Instead of the traditional sense of power amplifier. Input type: DC input, positive common end.

Input points: 8 points.

Enter the response time: 1.5ms the following.

Rated input voltage / current: DC24V/5mA.

Output form: transistor output, leakage type.

Output points: 8 points.

OFF leakage current: 0.1mA.

Output protection function: No.

Rated load voltage / current: DC24V/0.5A.

External connection: 4 wire.

Fast connector type.

Simple wiring through quick connector.

Can be installed along the 6 direction.

MITSUBISHI PLC program simulation debugging

The basic idea of program simulation debugging is,

In order to facilitate the form of simulation to generate the actual state of the scene,

Create the necessary environmental conditions for the operation of the program.

Depending on the way the field signals are generated,

The simulation debugging has two forms of hardware simulation and software simulation. Drive: MR-H_AN series.

Rated output: 15KW.

Universal AC servo.

Servo driver (drives servo) also known as the "servo controller", "servo amplifier",

Is a kind of controller used to control the servo motor. Its function is similar to that of the frequency converter,

Belongs to a part of the servo system, which is mainly used in high precision positioning system.

In general, the servo motor is controlled by position, speed and torque in three ways,

To achieve high precision positioning of the transmission system, the current transmission technology is the high-end products.

Servo drive is an important part of modern motion control,

Is widely used in industrial robots and CNC machining centers and other automation equipment.

In particular, it has become a hot research topic in the field of servo drives for the control of AC permanent magnet synchronous motor.

Current, speed and position 3 closed loop control algorithm based on vector control is widely used in AC servo drive system.

The speed closed-loop design of the algorithm is reasonable or not, for the entire servo control system,

Especially the speed control performance plays a key role.

HC-RF353B Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-RF353B&select=5

...more relevant model market price >>>>

Related products

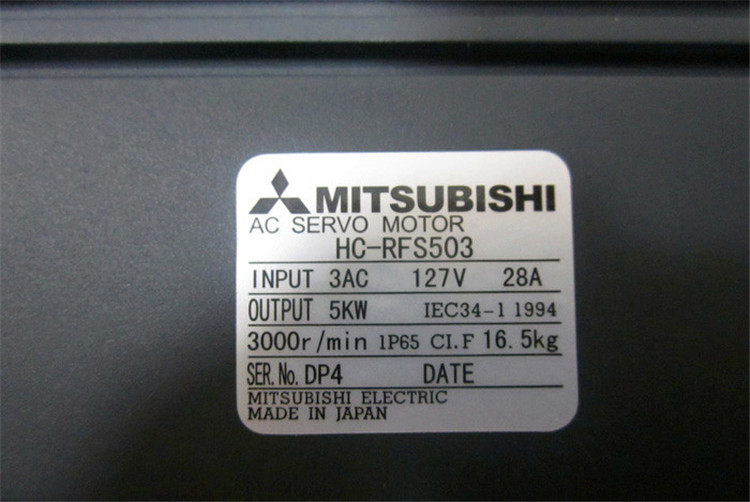

MITSUBISHI

Ultra low inertia medium power motor

HC-RFS503

Motor series: super low inertia, medium

MITSUBISHI

Low inertia medium capacity motor

HC-RF503

Motor series: low inertia, medium capaci

MITSUBISHI

Ultra low inertia medium power motor

HC-RFS203

Motor series: super low inertia, medium

MITSUBISHI

Low inertia medium capacity motor

HC-RF353

Motor series: low inertia, medium capaci